USG Corp (United States Gypsum ) (and indirectly through USG Canada Mining and CGC (Canadian Gypsum Co)) has announced that its Fundy Gypsum Co operation is to be closed permanently. The quarries at Wentworth and Miller's Creek, just north of Windsor, NS and the storage and port facilities at Hantsport, just to the west of Windsor were once a mainstay to the local economy. The operation has been inactive for most of this year, due to the sluggish US construction industry, the destination for most of its product, and only a skeleton maintenance staff have been kept on. No gypsum has been shipped in months.

This is a sad end to a unique operation which used an abundant local mineral (there is lots of gypsum left in the ground, but synthetic gypsum and the economy have left the industry devastated.) The mine and port were joined by a railroad, the Windsor & Hantsport, a short line that was once part of Canadian Pacific's Dominion and Atlantic Railway (DAR.) Fundy Gypsum was the line's only customer recently and it has also been shut down.

The port of Hantsport, once a booming shipbuilding centre in the age of sail, is home to a huge warehouse and modern shiploader which have been idled since the last ship was loaded earlier this year. The tug

Spanish Mist which was owned by CGC, was sold in the spring to the Magdelan Islands.

The other Hantsport Industry CKF (Canadian Keyes Fibre) now uses recycled paper as the main component of its paper products, and no longer brings in pulpwood or wood pulp by water to its mill as it once did.

Gypsum Transportation, the shipping arm of USG, and prior to that Fundy Gypsum itself were operators of many notable ships over the years, usually with the prefix "

Gypsum" but sometimes commemorating important personages, and since World War II all self-unloaders.

Its most recent fleet upgrade saw two new self-unloaders,

Gypsum Centennial built in 2001 and

Gyspum Integrity built in 2008. Ostensibly sister ships, they could carry 42,000 tonnes, and unload gypsum at a rate of 3,000 tonnes per hour. These ships have now found work in other bulk trades.

Hantsport posed an interesting challenge due to its tidal range in excess of 50 feet - the largest of any commercial port in the world. Ships had to arrive in port on a rising tide (the wharf dried out at low tide) and sail on the high tide or risk being stranded. Loading time was 3 1/2 to 4 hours, and the ship had to sail no matter how much cargo had been taken on. The new ship loaders could load in excess of 10,000 tonnes per hour each. These were amongst the fastest loaders on earth when commissioned in 2004.

Gypsum Centennial loaded January 2, 2011 in 4 hours and six minutes, but loaded to less than capacity because of the lack of demand at the other end. At that time it was reported that there might be one or two more shiploads left in the warehouse.

At its peak the port saw up to a dozen ships a month and exported 2 mn tonnes of gypsum a year. The material went to such ports as Boston, Stoney Point, NY, Norfolk, Baltimore, Savannah and Tampa. Several of those plants have now been shuttered. USG still operate a mine in Cape Breton and ships through Little Narrows, NS, which is a seasonal port on the Bras d'Or Lakes. Some of its product goes to Quebec and Ontario for use in cement manufacturing, but even that trade is threatened.

Some member of the Gypsum fleet:

1.

Gypsum Empress and sisters

Gypsum Countess,

Gypsum Duchess were of the second generation of self-unloaders built after Word War II. Built between 1956 and 1960 in France and Germany, they were 10,000 deadweight ton steam ships. They had small general cargo holds forward, and self unloading gear conveyors recessed in the house aft. The photo was taken in Halifax when winter ice closed both Hantsport and Little Narrows.

2

. Gypsum King commemorated J.B.King the guiding force behind gypsum operations from the 1890s to 1924. The ship was built in Collingwood ON in 1975 and was a 12,272 deadweight tonne steam turbine ship. It could unload at 1800 tons per hour using a retractable shuttle conveyor. It is shown here in Halifax going into drydock.

4

. Gypsum Baron was also built in Collingwood in 1976. It is shown leaving Halifax in winter after loading at competitor National Gypsum's dock. On the rare occasions when Hantsport was blocked by heavy ice, Fundy Gypsum arranged for these loads. Spray has frozen to the ship's side.

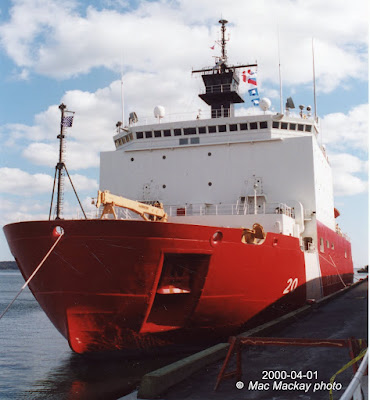

4.

A.V.Kastner approaches to old loaders at Hantsport on a rising tide. The tug

Spanish Misthas just turned the ship to face outbound and is nudging it to the dock while it stems the tide. The ship was built in 1987 and was 19,075 deadweight tonnes. It was sold in 2010 to Dubai, where it is trading as

Silica II (no doubt named for an abundant material in the United Arab Emirates.)

5.

A.V.Kastner in the new Gypsum Transportation colour scheme leaves the new dock with less than a full load. Cargo quantities were based on available loading time and demands by the processing plants and limited stockpile capacity. There was no time to secure hatches before the ship had to leave the dock with the falling tide. Its unusual self-unloader works over the stern and can slew to port or starboard.

6.

Gypsum Centennial at the new loader. The two spouts will keep loading until the last possible second. Each spout can swing on an arc and reach half the ship's hatches. The ship was built in Korea in 2001, and measured in at 47,950 deadweight. This was the ship's first visit to Hantsport. It was the first ship in the world to be fitted with the new Wartsila/Sulzer common rail fuel injection system. The engines were therefore supposed to be smokeless-you be the judge:

7

. Gypsum Centennial looks like a more conventional self-unloader. With sister

Gypsum Integrity, built in Brazil in 2008 to the same specification, these ships are now trading overseas.

.